Polycyanocrylates

Properties

Cyanoacrylates are commercially important monomers used for rapid-curing structural adhesives, also known as ‘‘Superglues" or "Krazy Glues". They polymerize in the presence of water, to be more specific, in the presence of hydroxide ions. For this reason, any slightly alkaline surface with trace amounts of adsorbed water will cure by first neutralizing the acidic stabilizers in the resin and then initiating rapid polymerization whereas acidic surfaces may delay or even prevent curing.

Because the presence of moisture causes cyanoacrylates to polymerize, exposure to normal levels of humidity in the air leads to the formation of a thin skin of cured resin within a few seconds. This greatly slows down polymerization. For this reason, cyanoacrylates have to be applied thinly to ensure that the reaction proceeds rapidly and a strong bond is formed within a reasonable time.

To facilitate easy handling, cyanoacrylates are frequently formulated with thickeners such as fumed silica to make them more viscous or gel-like. More recently, formulations have become available with new polymer additives that increase shear strength and toughness, creating a more impact resistant and robust bond.

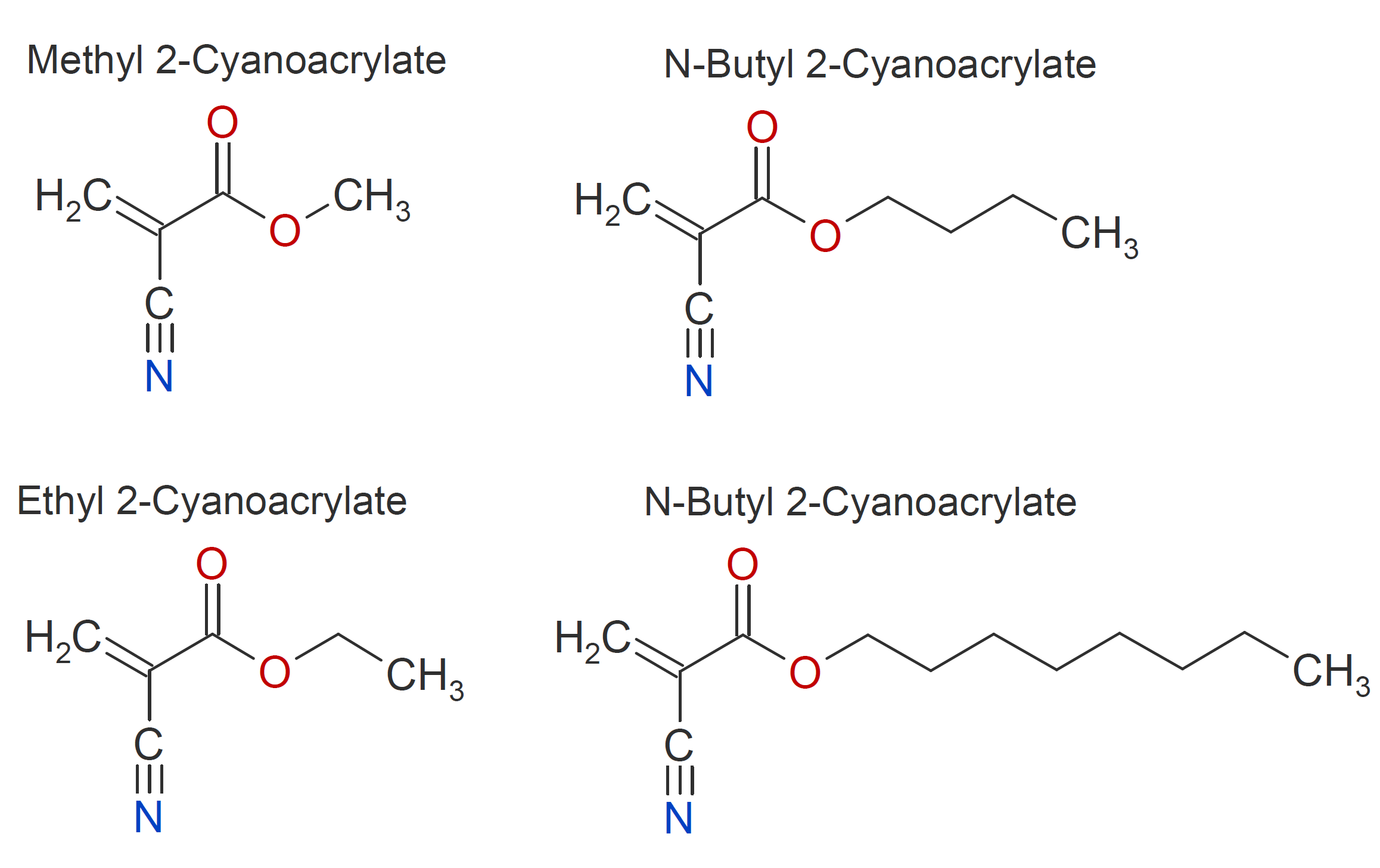

The most widely used cyanoacrylates include methyl 2-cyanoacrylate, ethyl-2-cyanoacrylate, n-butyl cyanoacrylate, and octyl-2-cyanoacrylate (used in medical, veterinary and first aid applications). The latter was introduced to address (minor) toxicity concerns and to reduce skin irritation and allergic response.

COMMERCIAL Polycyanoacrylates

Cyanoacrylates are sold by many adhesive companies. Two well

known trade names are Super Glue® and Krazy Glue®.

Other important manufacturers are

Permabond (Eastman 910®), and Henkel (Loctite 4XXX®).

Click the link below to see a list of

major manufacturers of cyanoacrylate resins and adhesives.

APPLICATIONS

Cyanoacrylates are mainly used as fast-curing adhesives in industrial, medical, and household applications. They bond a variety of substrates including metal, plastic and glass. However, unlike many other adhesives, they do not fill spaces. In fact, a very thin layer bonds more effectively than a thicker one that might not cure properly. Their effectiveness in bonding metal and their general versatility have made cyanoacrylates very popular.

Major drawbacks of cyanoacrylate adhesives are their short shelf life (one month once opened, but one year unopened) and the lack of impact toughness (brittleness).

Recently, cyanoacrylate formulations have become available that have overcome some of these problems. These adhesives systems also bond a number of substrates that older generations of cyanoacrylate glues did not bond. This has opened up new applications for this class of adhesives.

THERMO-PHYSICAL PROPERTIES